There was a time when we contributed to industrial production mostly through manual labor—from printing out sheets or buying huge computers to facilitate our work processes to hand welding all the parts of a car. In a nutshell, we used to spend a good amount of time using manual labor to create products. This is not the reality for the manufacturing sector anymore, or at least it is no longer a necessity as we have more evolved tools that can communicate with each other to make work simpler. We have ways to reduce general production costs, made possible through global scalability and 360-degree visibility of our businesses.

As demand is getting stronger and stronger every day, the competition to achieve custom orders for high-end secure setups is getting more difficult. To facilitate these custom setups, innovative ideas need to be heard by the right people. A network of resources plays a significant role in any industry. It is always more productive in the long run to be able to rely on subject matter experts (SMEs) available through a network of vendors.

How is manufacturing changing?

The manual labor industry is slowly becoming an automated industry in which robotics and mechanics play a vital role in achieving the production demands of consumers. Today, machines often compensate for the lack of an available workforce to meet market demands. The IT boom of the last decade brought industrial resources together so that managers have a better understanding of what’s happening on the production floor.

We are living in a world of permanent and constant technological revolution. The IIOT (Industrial Internet of things) is a transformative development that could allow numerous industrial machines to communicate with each other over the internet, which will bring massive potential to change the way we conduct business as well as how we manage production. Companies like General Electric, Shell, and many others are continuously making a move to cloud technology, decreasing maintenance and increasing production—translating to overall success.

New concerns on the table

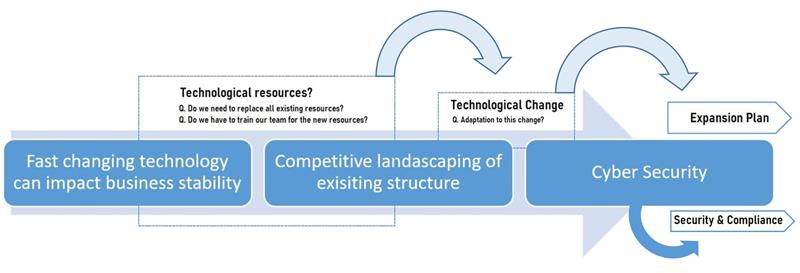

Enterprises and SMBs often struggle to find the right solution for their industry, and many factors need to be considered before a big jump. New technology means the big picture needs to be kept at the forefront while also working on the more granular details. You’ll want to think of basic concerns like:

- Replacement of your technological resources:

- Do we need to replace all existing resources?

- Do we have to train our team for the new resources?

- Technological change: Whenever businesses are adapting to technological changes, there will be training needs for personnel.

- Expansion plan: If we are expanding, how will data management be handled?

The above questions and concerns should trigger the IT development teams into a planning frenzy. They’ll evaluate, getting a complete view of their resources and requirements to determine what their company needs to bring in one unified solution. Immediate challenges will mostly come from the adaptation of the latest technological trends.

The challenges of security

Many questions can arise and impact your enterprise. With the right consultative team, questions will be easily answered, and they will put the resources together for you. But the greatest challenge that can slow down the process is cybersecurity.

Security is a great challenge for any business making the move into the digital world. But luckily there are many tools available to ensure you have a secure environment that will function through thick and thin. From Endpoint protection to Email protection while making sure you have a simple and efficient disaster recovery plan, you can make your environment as secure as possible.

New tools are available in manufacturing

Combining industrial resources can be done through IIOT. This is a scenario in which uniquely identifiable information is gathered through sensory devices, transmitting massive amounts of information. IIOT data can be anything from employee scheduling to defects on one of your welding robots. As organizations realize the value of adapting their intelligent assets, it will bring disciplined controls. The resulting optimization of information will improve output and streamlining.

Some of the benefits after adaptation of technology:

- Increase in revenue

- Enterprise-wide traceability

- Employee productivity

- Cost reduction

- Efficient resource management

- 100% process optimization

- Data-driven sensory awareness and analytics

- New technological business model with the ability to innovate

- Self-driven triggers

- Better experience

How it’s done

Technology convergence and applicability will be driven through different platforms. From your existing IT resources, GPS location, data governance, sensory database e.g., SCADA, smart sensors, MDM, etc., to individualized workflow in plant floors, assets controls, quality controls and testing, product locations, tagging, and many more areas. All can be controlled by a handful of applications to bring a 360-degree view of your company.

Countries across the globe consider the manufacturing sector to be one of the key areas which will improve the economy of the country. IIoT is one of the top enablers for the digital transformation of existing manufacturing environments in a fast-growing industry. It will be a gateway for commercial vendors to enter the manufacturing space.

How Sherweb can help

At Sherweb, we thrive in helping our partners and customers grow their businesses. We do this by offering a portfolio of products that will help any business in their digital transformation. We offer support to bridge the gaps in your IT development teams. We can cover productivity, CRM security, or even technical support requirements, all in a SOC 2 compliant environment. If you’d like to know more about how Sherweb can help you grow your business, contact us or check out our Partner Guide.